Synthetic Compostable Bioplastics

Developing chemical technology to produce the next-generation bioplastics without fermentation: Synthetic PHA

The problem

Virgin plastics are hardly replaceable

Recycling cannot prevent plastic pollution and microplastic accumulation

Biobased polymers cannot be the scalable and cost-competitive alternative

The solution

Competitive compostable bioplastics from CO2

-

Sustainable resources

-

Compostable

products -

Competitive

prices

The material

Polyhydroxyalkanoates

Polyhydroxyalkanoates (PHAs) are a group of plastics that cooperate with nature everywhere in every situation.

PHA behaves like plastics and degrades like paper. It decomposes at the bottom of the ocean, but not on your kitchen table.

At large scale, the chemical production costs are very close to bio-polyethylene. Synthetic PHA is likely to become the compostable plastic with the lowest costs.

The technology

Scalable production

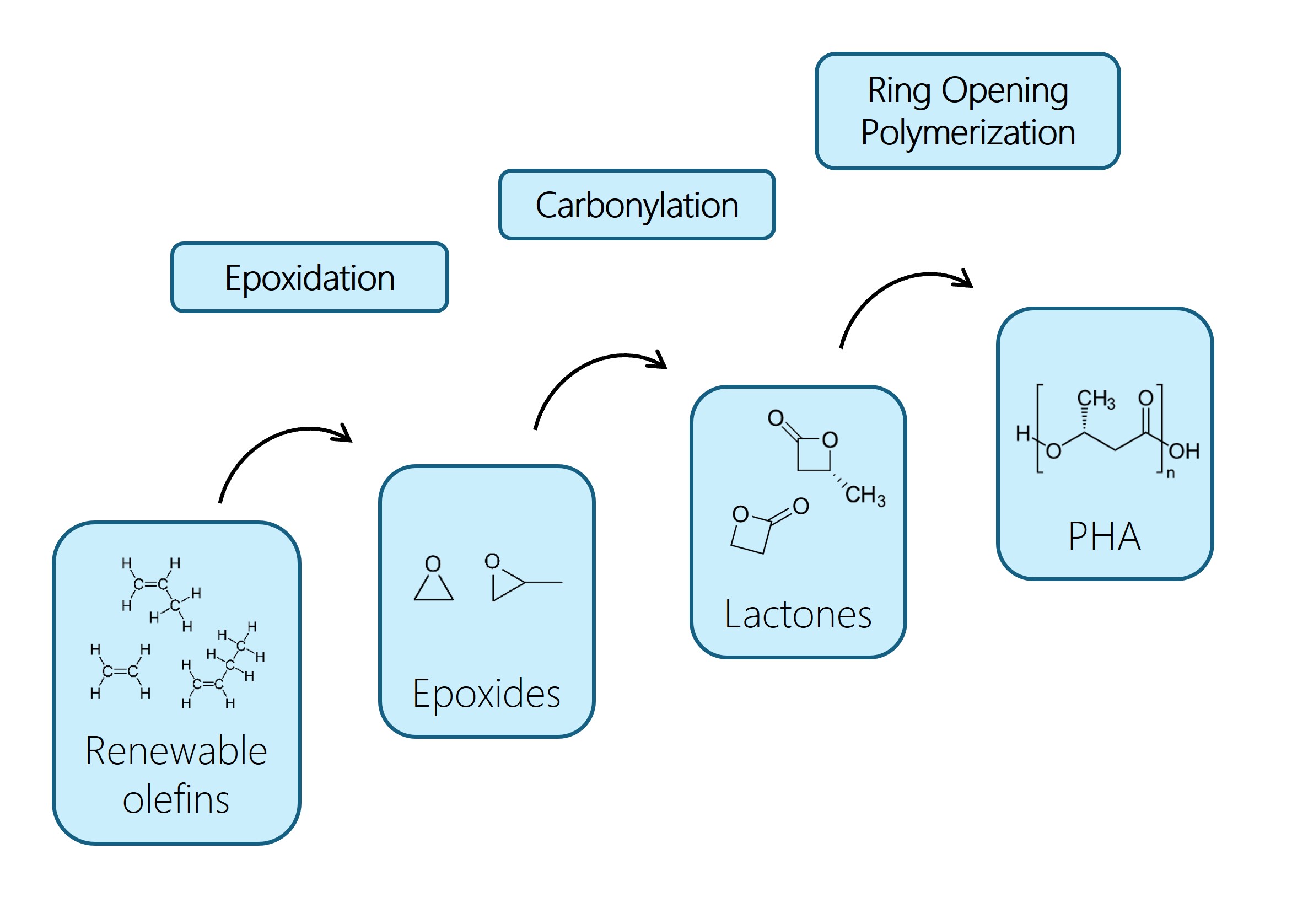

The highly competitive plastics industry requires the efficiency of petroleum technology to be employed in the development of next-generation bioplastics.

At YoungPolymer, we develop the production of P3HP, a type of PHA that can replace polyethylene for many uses:

Elongation at break: ~600%

Young's Modulus: ~0.3 GPa

Melting temperature: ~80°C

Glass-transition: ~ -20°C

Send us a message

Thank you for your message! We will contact you as soon as possible.